This page is a practical overview of our precision machining capability for high-accuracy components, built around two manufacturing bases in Suzhou and Wuhan.

If you want to move faster on quoting, include drawings, material, surface requirements, and the dimensions you treat as critical. You can send them via info@workersbee.com .

Our Swiss-type machining capacity includes 66 imported Swiss-type machines from Tsugami and Citizen (Suzhou 48, Wuhan 18). Covered models include Citizen A20/A12 and Tsugami S206, BO385, BO325, BO265, BO205, BO204, and BO203, supported by automatic bar feeders. The line supports up to 6-axis automatic machining and multi-face turn-mill processing (front/back/side) in one setup.

Our machining center capacity includes 27 precision machining centers, with 16 equipped with a 4th axis and 1 with a 5-axis setup, enabling multi-face drilling, milling, and tapping in a single clamping.

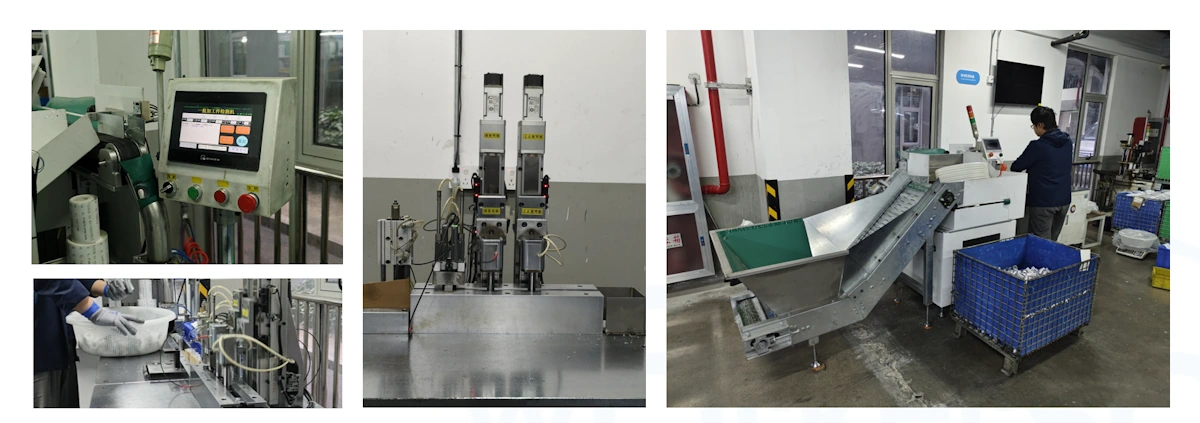

Quality support includes a dedicated inspection team of 25 and two automated inspection systems for inner diameter and overall length screening, with automatic sorting and counting.

Capability Snapshot

|

Area |

Best fit |

Typical part traits |

Quality focus |

|

Swiss-type turning |

Axis-based parts with tight concentricity needs |

Small diameters, slender geometry, multiple features aligned to one axis |

Coaxiality, burr control, repeatability across volume |

|

CNC milling (4/5-axis) |

Multi-face features or planar datums |

Cross holes, pockets, angled faces, complex contours |

Feature-to-feature position, clamping stability, batch consistency |

|

Secondary operations |

Appearance, edge condition, and cleanliness |

Deburr, uniform texture, clean parts ready for assembly |

Edge break consistency, surface condition, residue control |

|

Inspection and automation |

High-volume screening and stable measurement |

Inner diameter and length checks, sorting and counting |

Method alignment, reject logic, traceability |

Swiss-type machining is a strong choice when the functional datum is a cylindrical axis and several features must stay aligned to that axis. Fewer re-clamps usually means fewer opportunities for cumulative error.

Our Swiss-type turning line is built around Tsugami and Citizen equipment and is configured for multi-axis automatic machining with powered toolholders, enabling turn-mill compound processing across multiple faces while maintaining tight alignment to the main axis.

Milling becomes the main process when your geometry is dominated by planar datums, multi-face feature patterns, or pockets/contours that are inefficient in a turning-first path.

Our machining center footprint includes 4-axis and 5-axis capability to complete multi-face drilling, milling, and tapping under one clamping, which helps protect feature relationships and reduces positional drift across batches.

Many disputes in production are not caused by dimensions. They come from edge condition, surface uniformity, and cleanliness expectations that were not specified early.

We support common post-machining steps such as magnetic finishing, wet and dry blasting, centrifugal and vibratory finishing, and ultrasonic cleaning. This helps control burrs, surface appearance, and residues after cutting.

When additional surface processes are needed, we can coordinate with long-term partners for electroplating, anodizing, spraying, electrolytic polishing, and heat treatment.

Material choice affects tool wear, burr behavior, surface risk, and even how and when you measure.

We machine a broad set of metals and engineering plastics, including stainless steels (SUS303/304/316L, 630/17-4), steels (1215/1144/S45C), copper alloys (C3604/C3602 and related grades), aluminum alloys (6061-T6/6063/7075-T6 and others), engineering plastics (PEEK, PTFE, POM), and nickel-iron alloys in the Kovar family (4J29/4J36/4J42).

Materials Overview

|

Material family |

Examples |

What to watch |

What to clarify in the RFQ/drawing |

|

Stainless steel |

SUS303/304/316L, 17-4 |

Burr control, tool wear, surface consistency |

Functional surfaces, edge break, corrosion-critical areas |

|

Steel |

1215/1144/S45C |

Heat and finish stability, post-process needs |

Heat treatment needs, datum scheme, CTQ dimensions |

|

Copper alloys |

C3604/C3602 |

Smearing and burr sensitivity, surface marks |

Cosmetic vs functional surfaces, plating areas if any |

|

Aluminum alloys |

6061-T6/6063/7075-T6 |

Scratch sensitivity, edge integrity |

Handling notes, anodizing areas, surface class |

|

Engineering plastics |

PEEK/PTFE/POM |

Deformation and dimensional recovery, burr/stringing |

Measurement timing, fits, cleanliness requirements |

|

Nickel-iron alloys |

Kovar 4J29/4J36/4J42 |

Tight process control, tool wear |

Critical dimensions, inspection method, handling notes |

Good inspection starts with agreement on intent: which dimensions are critical, how to measure them, and what report format you want at each stage.

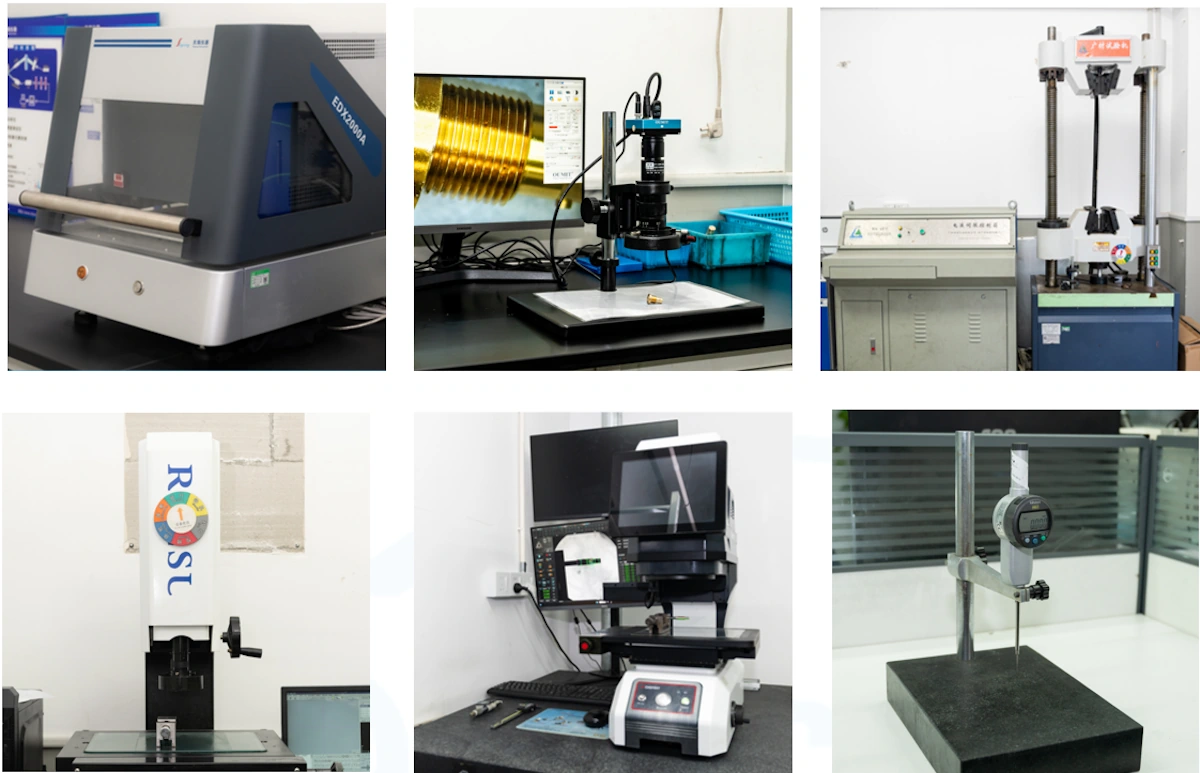

We support measurement and inspection with a dedicated team of 25, including image measurement, flash measurement, roughness measurement, coating thickness and video microscopy, plus standard gauges and micrometers for routine and precision checks.

For higher-volume screening, we use two automated inspection systems to check inner diameter and overall length. Inner diameter uses go/no-go gauging; overall length uses contact sensors. Nonconforming parts are automatically separated by defect type, and the system supports automatic counting.

We support precision components and related technical services for applications across optical communications, medical, automotive, liquid-cooling components, and connector-related parts.

Different industries emphasize different risks. Optical and connector-related components often focus on fit and surface condition. Medical components raise expectations around consistency, cleanliness, and inspection records. Automotive programs usually demand stable output at volume, where screening strategy becomes as important as machining itself.

RFQ and drawing review → DFM feedback → sample build → measurement report → pilot run → mass production → final inspection → packing and shipment

Faster projects usually start with clear CTQ dimensions, agreed measurement methods, and finish requirements that distinguish functional surfaces from non-functional surfaces.

|

Item |

What to provide |

Why it helps |

|

Drawings |

2D drawing + 3D model if available |

Faster review and fewer assumptions |

|

Material |

Grade/standard, and acceptable alternatives |

Process planning and surface risk control |

|

Surface requirement |

Target + where it applies |

Avoids cosmetic disputes and rework |

|

CTQ dimensions |

Identify critical features and datum scheme |

Aligns control plan and inspection effort |

|

Tolerances |

Tight zones vs relaxed zones |

Prevents unnecessary cost drivers |

|

Inspection needs |

Report type and sampling approach |

Ensures the right measurement resources |

|

Batch expectations |

Prototype / small batch / volume cadence |

Guides process choice and screening fit |

|

Packaging/labeling |

Protection needs and identification |

Reduces damage and mix-up risk |

|

Confidentiality |

NDA requirement if applicable |

Clarifies handling boundaries |

Ready to review your drawings. Email your 2D/3D files with material, surface requirements, and CTQ dimensions to info@workersbee.com, and note your target quantity (prototype, small batch, or volume). We will confirm manufacturability feedback and the inspection approach before sampling.